Shipwrights at Work

The work on Ernestina-Morrissey‘s rehabilitation is just amazing and beautiful. Much of the credit goes to the shipwrights who have the very best materials to work with.

A mortise is a hole or recess cut into a part, designed to receive a corresponding projection (a tenon) on another part so as to join or lock the parts together. Here you can see 5 mortises and the aftmost frame already in place.

One of the starboard frames ready to position, notice the tenon that will be inserted into the mortise.

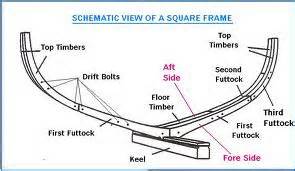

The frames of Ernestina-Morrissey are double-sawn (two separate pieces of wood fastened together). They are constructed of futtocks. Each futtock is shaped according to patterns from the lofting of the plans. Once the futtocks are shaped they are taken into the workshop for finishing.

The futtock is moved to the bandsaw where the tenon is cut. VIDEO and then to the planer where the surfaces are planed. VIDEO

The futtocks are then moved to a special work surface to be joined into the frames.

As the frames are assembled the planed surfaces of the futtocks are dressed with the same bedding as the butts.

Futtocks of live oak and white oak are both used in one frame. The live oak is used in the area of the frame with the more extreme curve. Notice the butts of the trunnels protruding from the sides,

Once the frame is assembled it takes its place in Ernestina-Morrissey.

Watch this series of videos to see the process of raising the frame. PART 1, PART 2, and PART 3

We’re sure you agree with us that this work is amazing and beautiful!

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Amazing Oak!

Materials procurement has been one important facet of this first year’s work by Boothbay Harbor Shipyard and with the help of Harold Burnham, DCR’s owner’s representative on the project, they have stockpiled some amazing wood including Danish oak and Georgian live oak for Ernestina-Morrissey’s rehabilitation.

The story of the Danish oak involves England and the Napoleonic Wars. After the neutral Danish fleet was confiscated by the British to keep it out of French hands, King Christian VII required that his lords plant thousands of oak trees on their lands to be raised for naval timbers. They were pruned and thinned until only the best were growing. Meanwhile warship technology moved to iron and steel and by the time the timber was ready it wasn’t needed by the Navy. It is now made available for special projects. And it was made available for the Ernestina-Morrissey due to her historical significance.

The US Navy has a white oak forest in Indiana for the USS Constitution..

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

The live oak was cut in Georgia at Cross Sawmill. Harold and Eric went to visit Steve Cross to check his operation. The grain and strength of the wood and the growth pattern of the trees make live oak the very best for shaping curved ship timbers. It is very heavy and hard to work. Green live oak is over 90 pounds per cubic foot.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Ross Branch developed a new technique to shape this hard to work wood.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

In addition to the oak, another wood that is valuable for building ships like Ernestina-Morrissey is old growth yellow pine. In 2009 Fairhaven Mills in New Bedford was demolished. It was built in the early 1890′s, about the same time as Effie M. Morrissey, and this is the type of wood that was used for the ship’s original deck in 1894. The southern yellow pine was valued for use as beams in large buildings as well as for ship building and in 2009, then Mayor Scott Lang facilitated the donation of the beams from the building to Ernestina. The city has stored the wood for use in the renewal of the aft deck during the rehabilitation of the stern.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

A Busy April in the Shipyard

The previous posts have described the process of cutting the futtocks. Here you see the futtocks fastened together to form a frame. The curves in the frames cannot be cut from a single piece of lumber so futtocks are sawn and fastened in pairs to form the frames. For a ship like Ernestina-Morrissey with a beautifully curved hull the curves of the futtocks are very complex. Notice that for Ernestina-Morrissey the futtocks are being fastened together with trunnels and the butts of the futtocks are spaced well apart from each other.

This is a cant frame and there is a floor across the bottom of it that will be bolted to the forward face of the stern post. The floor is bolted to the after futtocks with 3/4 bronze bolts. photo credit: H. Burnham

The leftmost vertical structure in the photo below is the stern post that the cant frame will be attached to.

The stern structure is taking shape on Ernestina-Morrissey. The transom will be fitted to the end of the horn timber.

The stern post, rudder post and horn timber have been fastened to the keel. A recent post showed all these parts being dry fit in the workshop. Now they are part of the Ernestina-Morrissey.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Cutting Futtocks from Live Oak

Ross Branch, one of the shipwrights working on the Ernestina-Morrissey project at Boothbay Harbor Shipyard has developed an ingenious way (Patent Pending) to use a special chain saw to cut the live oak futtocks for the ship. Notice the guide attached to the chain saw blade.

A track is made from the patterns, incorporating the angles from the ship's plans for the chain saw to follow . photo credit Ross Craft Branch

A piece of live oak is chosen that can accommodate the curve of the futtock to be cut. The wood is lifted onto saw horses and the pattern is traced onto the wood with the notes for the angle of the cut. Wedges with the correct angle hold the track in place. It is worth noting that live oak has a density of 90 pounds/cubic foot when it is green (63 pounds/cubic foot dry). Fork lifts are used to move the timbers.

You can see how closely the angled chain saw cut matched the pattern. photo credit Ross Craft Branch

Once the curve it doesn’t need much planing to smooth it off. VIDEO

This technique uses less manpower and is less wasteful than using the ship saw with the heavy live oak. photo credit Ross Craft Branch

Read more from the Boothbay Register.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Futtocks and Frames Beginning to Take Shape

The framing of a ship the size of Ernestina-Morrissey cannot be cut from a single piece of wood so futtocks are cut and paired to form the frames as shown in this schematic. Care is taken to make sure that where the butts of the individual futtocks meet there is a sufficient separation from the joint in the sister futtock in the same frame.

The process starts at the lofting table and patterns are made for each futtock.

Some of the pieces have very complex shapes especially in the bow and stern where the curve of the hull changes quickly over a short distance.

Live oak has been purchased from Georgia. This wood makes good curved structures because of branching growth pattern and complex grain. It is very hard and heavy and difficult to work with.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

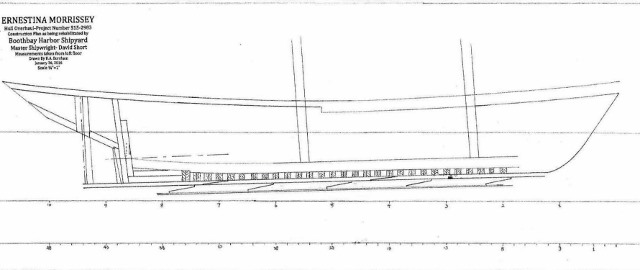

Lining Up the Keel

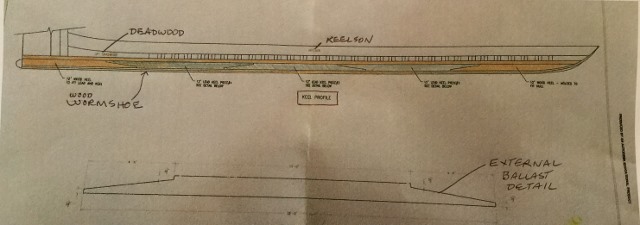

The pieces of keel have been rolled into place and the top is being fit into place. The four 15,000 pound lead pieces will be jacked up to be joined with the wood along with the scarfed wood keel end timbers. Finally a worm shoe will be added along the length of the new keel.

The forward part of the keel has already been fitted to the forefoot. Some of the futtocks you can see here are African hardwood from the repairs done in Cape Verde.

Braces hold the keel in position as the keel is fit to the structure of the ship. You can see the grey painted lead section resting on supports ready to be jacked into place.

The keel is too long to be able to use one length of wood so the shipwrights need to join the timbers. David is putting the final touches on this scarf in the Danish oak. The rabbet in the top of the timber is shaped to meet the five inch garboard.

David and Ross working to bring the top keel timber up to alignment using a come-along. You can see the oak timber which is the aft section of the keel already in place ready to be jacked up. The forward end of this timber will be scarfed into the lead.

Here’s another look at the plans.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Stern Structure Taking Shape

Ernestina-Morrissey‘s stern needed to be entirely rebuilt, as you could tell from the photos posted previously. While the new keel is being moved into place the shipwrights are working on the timbers that will provide the frame for the stern. Here is a photo to use as a frame of reference for the new structures that are being shaped.

The workers here were removing the rudder in July, 2015. The rudder is at the right on the fork lift. You can see the rudder stock going up into the passage in the rudder post which supports the rudder. In the space to the left of the rudder post you can see the three blades of the propeller and the stern post running up from the keel into the hull.

Here are the new timbers of Danish oak to compare.

Here is the new structure, new stern post on left, rudder post on right. The diagonal is called the forward horn timber. The frames and planking will be attached to it. The structure above the horn timber will be inside the hull. At the left, lined up with the horn timber, you can see the passage that the rudder stock will pass through. photo credit - Harold Burnham

You can see how massive the timbers are.

stern timbers - Backbone, photo credit Ross Branch This photo was taken before the horn timber was fit, but you can see the deadwood forward of the stern post.

All the pieces were dry fit in the workshop. Below is the transom structure. The “outboard” side of the transom is up in this photo, the curved pieces frame the bottom of the transom. The aft horn timber extends from the bottom of the transom toward the doorway. The cheeks make it look like a clothespin. The open part will be fit to the rudder and stern posts.

The stern structure will be erected as soon as the keel is ready.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Getting the New Keel Ready

In the latest set of photos from the shipyard you can see how the lead ballast will fit into the new keel.

Capt. Dave Thompson standing next to the aft end of the new keel for scale. The grey part is the four sections of lead ballast. The ends of the keel will be faired into the hull. photo credit Harold Burnham

Looking toward the forward section of the keel, each of the four sections of lead ballast weighs 15,000 pounds. photo credit Harold Burnham

The Danish oak and lead sections are scarfed together. The top of the keel is rabbeted to receive a 5 inch garboard along most of its length. photo credit Harold Burnham

The shipyard crew is constructing a ramp system to bring the keel in place under the ship. photo credit Harold Burnham

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

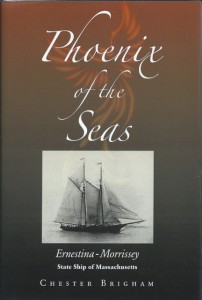

The Rebirth of the Ernestina-Morrissey

Ernestina-Morrissey will be featured in the April 7 lecture of the New Bedford Whaling Museum’s 2016 Sailors’ Series “A Century of Design & Invention”.

Whaling Museum’s 2016 Sailors’ Series “A Century of Design & Invention”.

Chester Brigham, author of ”Phoenix of the Seas” will recount the journeys and travails of the Ernestina-Morrissey, State Ship of Massachusetts. The schooner, repeatedly written off as doomed, is now undergoing a hull rehabilitation at the Boothbay Harbor Shipyard in Maine, phase 1 of a complete restoration.

Master Shipwright David Short, Project Manager for Boothbay Harbor Shipyard and Captain Harold Burnham, DCR’s Owner’s Representative, will provide insights into the restoration project ongoing in Maine.

Copies of “Phoenix of the Seas” will be available for purchase.

This is a ticketed event.

Lecture Registration: Single Lecture: Whaling Museum Members $15 / Non-Members $20

For tickets: Order Online or call 508-997-0046 ext. 100.

SCHEDULE

Each lecture starts at 7:00 p.m. in the Cook Memorial Theater with a pre-lecture reception at 6:00 p.m. in the Jacobs Family Gallery.

If you cannot attend you can order your copy of “Phoenix of the Seas” online.

This entry was posted in Membership and Outreach Committee, News. Bookmark the permalink.

What’s Old is New Again

The lead ballast removed from Ernestina-Morrissey last summer has returned to Boothbay Harbor Shipyard.

As the lead was removed from the bilges it was stacked on pallets.

The plans for the present rehabilitation include a keel with external ballast.

The wood keel on the ship is being removed. Judging from the type of wood, identified as pine from Portugal, the keel was replaced during the reconstruction in Cape Verde. The wooden parts of the new keel will be made of the Danish oak now curing in the sheds of the shipyard.

Download January 26, 2016 Construction Plan.

The pallets of lead were delivered to the foundry where the lead was recast. The external ballast sections were delivered to the shipyard recently.

The sections of external ballast for the keel have been delivered from the foundry. photo credit Harold Burnham

It is exciting to know that the dismantling of the ship is well underway and the restoration is beginning! Check back often for the latest news!

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.