Lining Up the Keel

The pieces of keel have been rolled into place and the top is being fit into place. The four 15,000 pound lead pieces will be jacked up to be joined with the wood along with the scarfed wood keel end timbers. Finally a worm shoe will be added along the length of the new keel.

The forward part of the keel has already been fitted to the forefoot. Some of the futtocks you can see here are African hardwood from the repairs done in Cape Verde.

Braces hold the keel in position as the keel is fit to the structure of the ship. You can see the grey painted lead section resting on supports ready to be jacked into place.

The keel is too long to be able to use one length of wood so the shipwrights need to join the timbers. David is putting the final touches on this scarf in the Danish oak. The rabbet in the top of the timber is shaped to meet the five inch garboard.

David and Ross working to bring the top keel timber up to alignment using a come-along. You can see the oak timber which is the aft section of the keel already in place ready to be jacked up. The forward end of this timber will be scarfed into the lead.

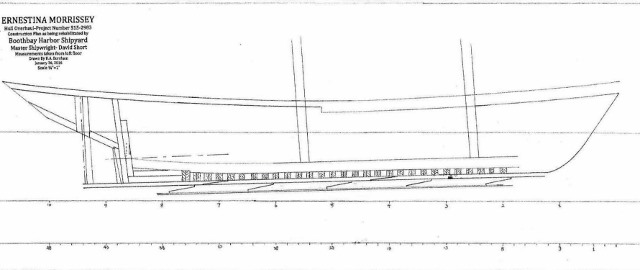

Here’s another look at the plans.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

← Stern Structure Taking Shape | Futtocks and Frames Beginning to Take Shape →