Futtocks and Frames Beginning to Take Shape

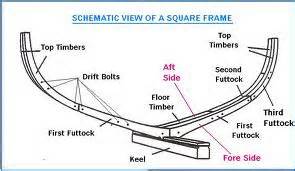

The framing of a ship the size of Ernestina-Morrissey cannot be cut from a single piece of wood so futtocks are cut and paired to form the frames as shown in this schematic. Care is taken to make sure that where the butts of the individual futtocks meet there is a sufficient separation from the joint in the sister futtock in the same frame.

The process starts at the lofting table and patterns are made for each futtock.

Some of the pieces have very complex shapes especially in the bow and stern where the curve of the hull changes quickly over a short distance.

Live oak has been purchased from Georgia. This wood makes good curved structures because of branching growth pattern and complex grain. It is very hard and heavy and difficult to work with.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

← Lining Up the Keel | Cutting Futtocks from Live Oak →