Trunnels

The planks are being attached with silicon bronze screws and trunnels. A trunnel (tree-nail) “is like a large dowel, pounded into a hole drilled through the pieces of wood to be fastened together, and set by pounding wedges into both ends, so that the treenail will not come out.”

Willy is measuring where the fastenings are in the frame and making notations on the plank below. When the next plank is clamped in position the crew can refer to the notes when they drill the holes for the fastenings.

As the holes are drilled the ceiling clamps hold the plank tight to the frame and to the adjacent plank. The butt end of this plank is already fastened with silicon bronze screws. Notice as well the 5 inch garboard and 4 inch broad strake. The rest of the planking is 3 inch.

The trunnels on the left have been pounded in and need to be trimmed flush with the plank and wedged. Those on the right need to be fully set into the frame.

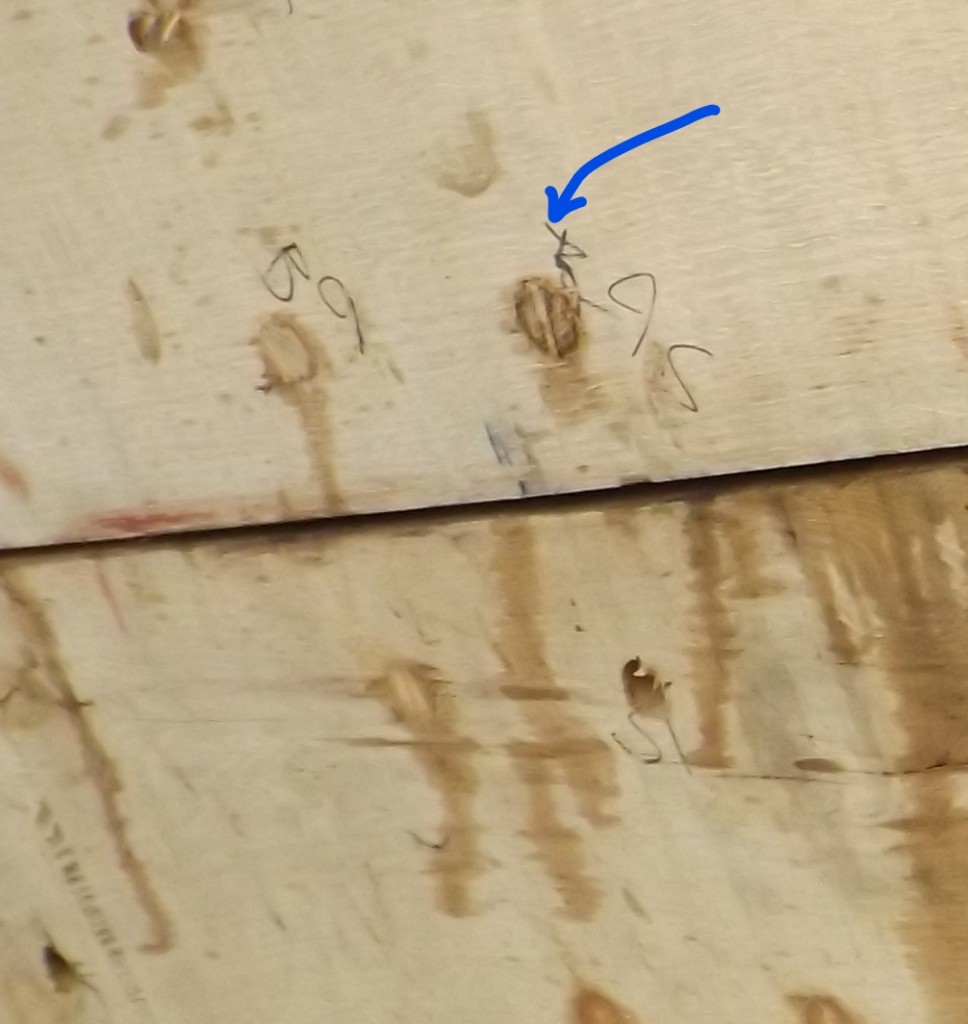

A wedge is driven into the locust trunnel to make it tighter. Notice the wedge is driven in at right angles to the grain of the plank to avoid splitting the plank.

This Project is being supported with funds from the City of New Bedford’s Community Preservation Act Program,

You can easily access all our posts about this project HERE.

To help support this project please press the yellow DONATE button at the right.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

← Fairing and Caulking | Shutter Plank In! →