Progress in the Shipyard – February 22, 2021

If you are looking for new, up to date Progress reports, they are HERE

Thank you, Bristol Marine, for sharing the latest news of the great work your crew is accomplishing during the pre-launch fitting out of Ernestina-Morrissey! In the attached series of photos, you will see progress on the restoration of the Ernestina-Morrissey at Bristol Marine’s Shipyard in Boothbay Harbor. Currently, all work on the Ernestina-Morrissey at the Shipyard is being funded through the generosity of the Lenfest Family.

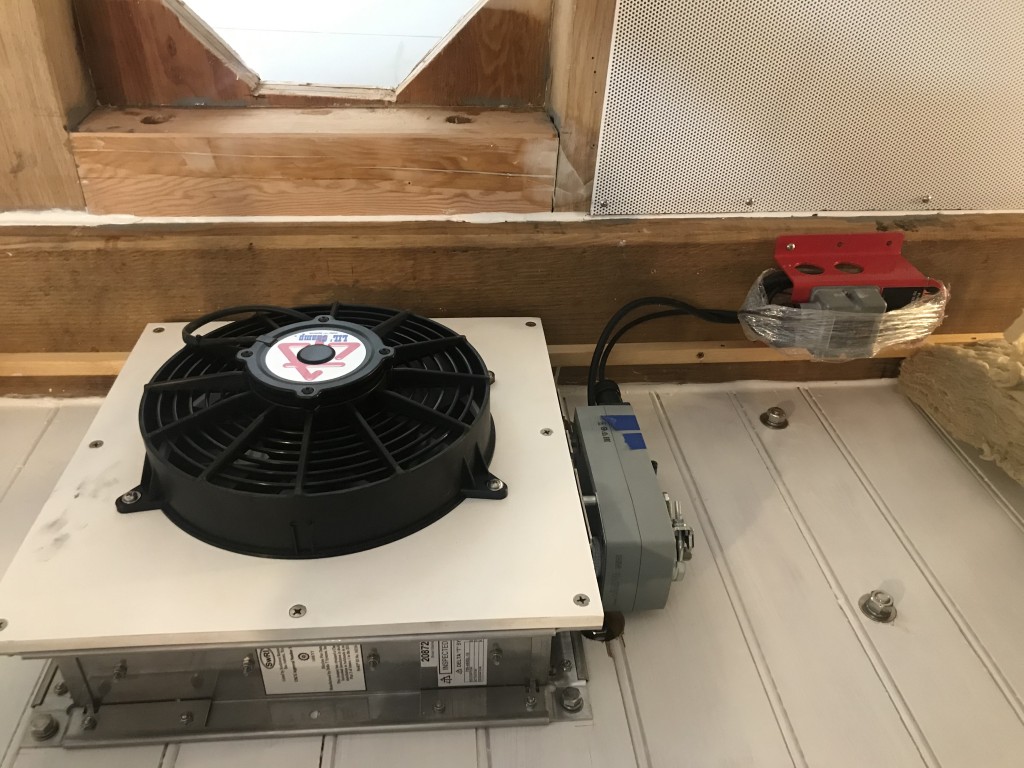

1. Engine Room Exhaust

We recently saw the installation of an 11" electric ducting exhaust fan in the engine room. This fan is located just below the starboard side ventilation box, and is designed to help pull a sufficient amount of air through the engine room for the engines in that space to operate properly. This is a high-quality component that looks very nice alongside all the other quality components being installed in the ship.

2. Foc’sle Head

While our plumbing team has moved into the main cabin, our carpenters have been able to revisit the Foc'sle space and continue with accommodation installations. This head cabinet is beginning to take shape. The door for this head is built and currently being painted. Very soon we will see the vanity, sink, and toilet being installed.

3.Galley Counter

Like the head space, our carpentry team was forced to slow progress in areas of the Foc'sle while the plumbers did their work. The galley space is now back on line as David Short has returned to the more intricate custom countertop and cupboard installation. This week we are expecting to see the galley sink fitted in this assembly as we get closer and closer to a complete cabin.

4. Main Cabin Accomodation

This image shows progress on multiple aspects of the project. Along the fore and aft stringer you can see wastewater drainage plumbing integrated into the bunk structure. The crew has been communicating and working well together as installations are overlapping more and more. Coordination is critical to this final push through the ship to complete the interior and more attention to details like this will help us achieve our goals on time.

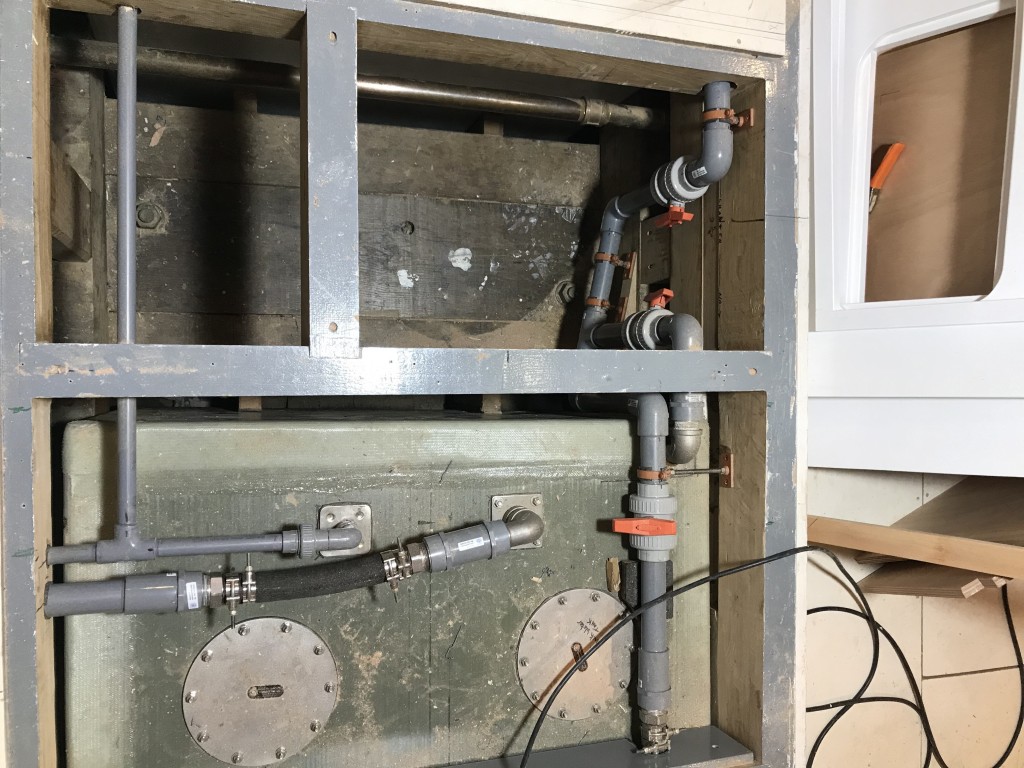

5. Main Cabin Plumbing

There is no such thing as a simple installation on a ship. Every component going into this vessel is custom designed and often takes creative installation methods to fit and work properly. The plumbing system is a great example of this. This one image of a relatively minor aspect of the waste water plumbing system shows 28 different connections and 8 different types of components in order to make the system work properly through this particular space.

6. New Generators

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

← Meet Tiffany Krihwan, Ernestina-Morrissey’s New Captain! | Ernestina-Morrissey – One Ship, Many Lives →