Ernestina-Morrissey Arrives in Homeport New Bedford!

Ernestina-Morrissey‘s crew arrived in New Bedford where more work must be completed before final Coast Guard inspections can occur.

There will be no public access to the vessel until Ernestina-Morrissey receives her full Coast Guard certifications.

Check the SEMA Facebook page and the SSV Ernestina-Morrissey Facebook page for frequent updates! And check the comments there for more photos.

The crew took a brief weather window on Tuesday, November 29 and departed Massachusetts Maritime Academy with little public notice. Buzzards Bay was calm and although the temperature was low there was little wind and with an early start they arrived in New Bedford before noon.

This entry was posted in News. Bookmark the permalink.

Ernestina-Morrissey Arrives at Massachusetts Maritime Academy.

We knew the crew was waiting for a weather window but didn’t know when that would be. The news came from Bristol Marine’s Facebook Page Thursday evening, which included a link to follow the voyage. The news spread and we shared that post on the SEMA page early Friday morning. By mid-morning Ernestina-Morrissey was approaching the east end of the Cape Cod Canal almost ready to start her next life with Massachusetts Maritime Academy. Ernestina-Morrissey means a great deal to many people who have connections to her many adventures since 1894. Some of them headed to the Cape Cod Canal and the viewing areas there. We are immensely grateful to those who sent these images to share with you! Check the SEMA Facebook page for frequent updates! And check for photos in the comments.

Tally Garfield was waiting on the breakwater near Scusset Beach to be one of the first to welcome Ernestina-Morrissey to Massachusetts. Photo Credit Tally Garfield

Approaching the Sagamore Bridge from the Cape Cod side of the canal. Photo Credit Ellen Madigan Newman She posted many on the Facebook page.

Gene Monteiro, former Schooner Ernestina commissioner, sent this fabulous video! Look how well she moves through the water! The Sagamore Bridge is at the beginning. The crew recognized the spectators onshore with a blast from Ernestina-Morrissey‘s horn. Credit Eugene Monteiro

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Ernestina-Morrissey Leaves Boothbay Harbor !

Ernestina-Morrissey left Boothbay Harbor yesterday evening and set a course south. She is now in Cape Cod Bay approaching the east end of the canal. Massachusetts Maritime Academy has a webcam streaming the Cape Cod Canal traffic. Here’s how she looked passing there 7.6 years ago heading for Maine! Ernestina-Morrissey is stopping at Massachusetts Maritime Academy today and is scheduled to return to her homeport New Bedford after Thanksgiving.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Repairing Ernestina 1

Almost a year ago we reported about the dories being moved to the Buzzards Bay Coalition’s Science & Field Operations Center in Marion. On December 16, 2021 Fred Sterner, former mate on Ernestina and also on the Schooner Ernestina Commission, began to work on Ernestina 1. You can see the progress below and know Ernestina 1 will be waiting at New Bedford State Pier when Ernestina-Morrissey arrives at her berth!

After considering the quicker commute and access to his tools, Fred moved the dory from Marion to his workshop. Work was slow until spring.

Needs scraping and cleaning and also notice the drain hole for when the dory on deck and the plug to remember when it is launched

Painted with Kirby's #9 Cream Semi-gloss: the new seat riser and old thwarts, which are removable so that the dories can be stacked on deck

Ernestina 1 ready for scraping, sanding and painting the outside, notice the Ernestina 1 in the bow.

~~~

See you on State Pier!

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

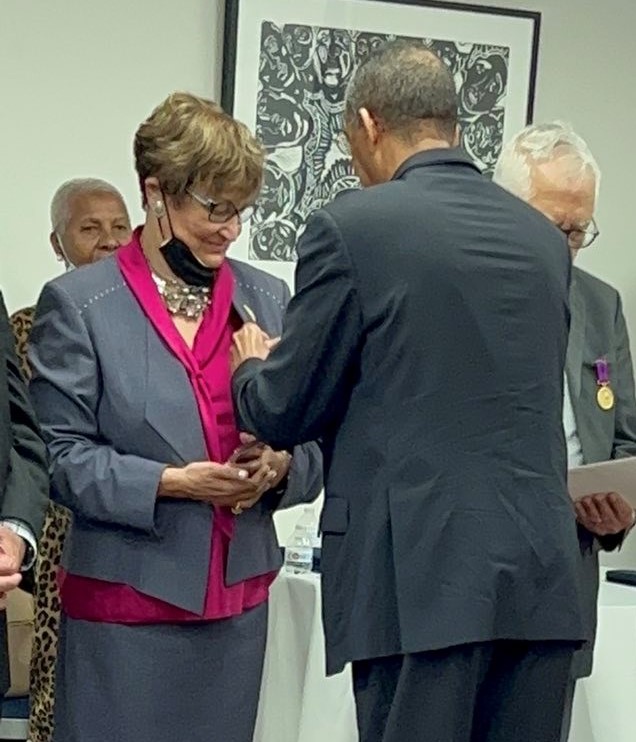

Laura Pires Hester Honored by Cabo Verde Government

An award ceremony was held at the Consulate General of Cabo Verde in Quincy, Massachusetts on November 4, 2022. Several Individuals were honored for their contributions. With the honorees in the center is Ambassador José Luís Do Livramento Monteiro Alves de Brito and to the right is Minister Plenipotentiary Octavio Bento Gomes

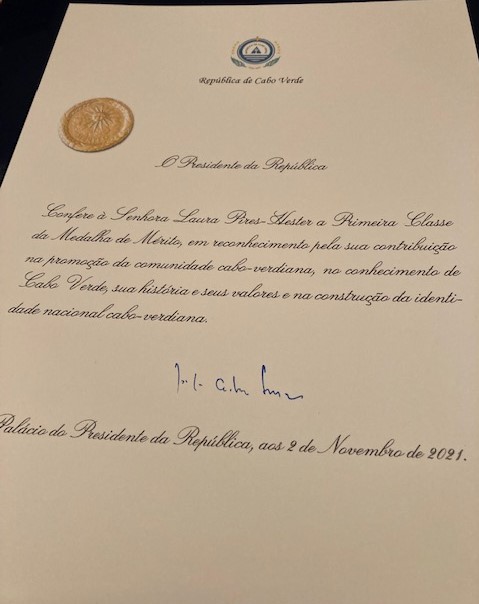

The Ambassador, José Luís Do Livramento Monteiro Alves de Brito presented Laura with a First Class Medal of Merit. The award was decreed by His Excellency the former President of the Republic, Dr. Jorge Carlos de Almeida Fonseca on October 29, 2021. Dr. Laura Pires-Hester, received the first class of the Medal of Merit, “in recognition of her relevant and meritorious contribution to the promotion of the Cabo Verdean community, to the knowledge of Cabo Verde, its history and its values and to the construction of the Cabo Verdean national identity.”

From the Consulate:

Dr. Laura Pires-Hester was born in Wareham, Massachusetts, USA, the daughter of Cape Verdean parents. She has always felt connected to Cape Verde and has spent many decades serving our community in the United States. Her life has effectively combined high academic achievement and professional contributions, while also characterized by active volunteerism. This combination has enabled her to build networks of individuals and organizations to support and empower the most disadvantaged sections of society. Her pragmatism, professionalism, humility, and persistence have made her a reference point for all. She has dedicated much of her career to creating and improving opportunities for underserved people and communities, including Cape Verdeans and other people of color who have been affected by inequities in American society.

Two books published in 2015 highlight her professional and volunteer work: Creating a College That Works: Audrey Cohen and Metropolitan College of NY, by Grace Roosevelt; and Phoenix of the Seas: Ernestina/Morrisey-State Ship of MA, by Chester Brigham.

Her doctoral dissertation, “A Study of Cape Verdean-American Ethnic Development: The Emergence of Bilateral Diaspora Ethnicity and Its Impact on a Southeastern New England Locality”, reflects her commitment to the Cape Verdean community.

A highlight of her accomplishments is undoubtedly Dr. Laura’s brilliant work with Michael Platzer in co-leading the National Friends of Ernestina-Morrissey. In this effort, they worked tirelessly and meritoriously with hundreds of individuals and organizations in Massachusetts, Connecticut, Rhode Island, New York, and Philadelphia to raise support and funds to restore and repatriate the historic Ernestina. This could not have happened without the government and people of the newly independent Cabo Verde, which resulted in Ernestina’s return as the amazing gift to “people of the United States” in 1982. Especially in this time of global polarization and strife, Dr. Laura believes that the unique Ernestina story (which is not yet finished) represents the kind of ethnic, cultural, economic, and geographic “crossing of boundaries” that are so needed both here and abroad.

This entry was posted in News. Bookmark the permalink.

Sea Trials!

A few days before the October Schooner Ernestina-Morrissey-Advisory Board Meeting the vessel underwent sea trials. Ernestina-Morrissey set out from the dock under her own power and the new engine, transmission and drive line performed well.

Representatives from Cummins Marine Power , TwinDisc Transmissions and Hundested Propulsion Systems were onboard for the hour-long trials and Ernestina-Morrissey‘s mechanical propulsion systems will only need a few minor adjustments.

Surely, when she sensed the open water of the Gulf of Maine she was ready to keep going but it was time to get back to the dock. Ernestina-Morrissey still needs the rest of the hardware installed on her spars and the running rigging completed; then the sails can be bent on.

Everyone onboard agreed that Ernestina-Morrissey‘s sea trials were a success.

Everyone onboard agreed that Ernestina-Morrissey‘s sea trials were a success.

If you want to hear the Cummins QSM 11 engine running visit the crew’s Facebook page. And like and follow the page to get more great posts!

Thank you to Bristol Marine’s Facebook page for the photos.

This entry was posted in Maintenance and Operations Committee, News. Bookmark the permalink.

Celebrating Cape Verde and Bridgewater State University

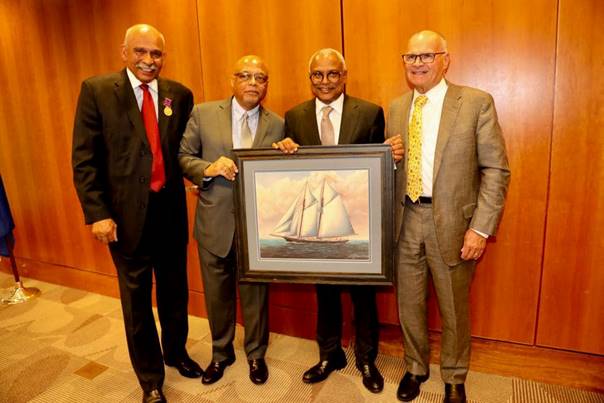

SEMA Director Mike Gomes, SEMA President Julius Britto, President of Cape Verde, Jose’ Maria Pereira Neves and SEMA Vice-President Bob Hildreth.

On September 22, 2022 Bridgewater State University celebrated 20 years of partnership with the Republic of Cape Verde. President Jose’ Maria Periera Neves was the honored guest. Mike Gomes, a member of the Board of SEMA, was presented with the highest civilian award that Cape Verde gives to an individual. Mike has worked over these 20 years to help establish the Cape Verde University in Cape Verde. He has been like a father to so many young Cape Verdeans at the Bridgewater Campus as well as the Cape Verde University campus in Cape Verde. Mike is also involved with the Pedro Pires Institute for Cape Verdean Studies at BSU.

At the celebration Bob Hildreth, SEMA vice president and Julius Britto, SEMA president, presented President Neves with a framed picture of the Ernestina. Painted by Jeff Eldrige in 1988.

This entry was posted in Membership and Outreach Committee, News. Bookmark the permalink.

A Message from Captain Krihwan ·

I am still looking for Deckhands, AB and a Cook. SSV Ernestina-Morrissey is in the water and we are currently up rigging the vessel. We plan to do our sea trials in Mid-October and the COI. After that is complete sail back to New Bedford. The starting pay for a deckhand is $2,200 a month and live aboard. The AB pay rate is $2,400 and live aboard. The Cooks pay rate is $2,800 and live aboard.

Want to be one of the first to sail on Ernestina-Morrissey in 2022? Check it out!

This entry was posted in Maintenance and Operations Committee, Membership and Outreach Committee, News. Bookmark the permalink.

Thursday September 1 A New Dock!

On Thursday September 1, Ernestina-Morrissey was moved “around the corner” to a new dock at Hodgdon’s Marina. With easy access back to the Shipyard and their berths, the crew will continue working on the vessel there. Rigging and ballasting and other preparations for sailing are on the work list. For the latest news visit and follow ssv.ernestins.morrissey Facebook page.

This entry was posted in News. Bookmark the permalink.

Tuesday August 30 at the Shipyard

With the railway cleared and no audience, Ernestina-Morrissey slid down the railway and was afloat!

Ernestina-Morrissey made her way down the railway without incident. Lines had been set for when she floated free of the car.

Captain Tiffany watches as the dock lines are led over the frame of the car to the dock. When they were ready the car could be pulled back into the Yard leaving Ernestina-Morrissey at the dock.

Fenders are set. Notice the car has been taken away. Her banner, fastened to the starboard side of the main boom doesn’t look too big anymore! Soon it will fly high!

There is still a lot of work to do before the boat leaves Boothbay Harbor. There are still equipment supply-chain problems including the watertight doors for bulkheads between the holds. Until they arrive and are installed as well as some other equipment, the boat cannot have the final Coast Guard inspection. The only timeline SEMA has been given for her arrival in New Bedford is “in the fall”